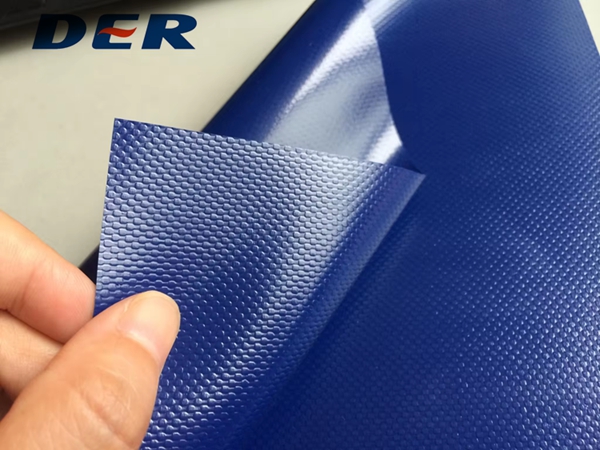

PVC TARPAULIN

- 2025-06-23

PVC Tarpaulin Thickness Specifications and Applications

I. Thickness Specifications & Parameters

| Thickness | Weight (GSM) | Tensile Strength (N/5cm) | Temp. Range | Primary Applications |

| Ultra-Thin (0.2-0.3mm) | 300-400 | 1500-2000 | -10°C~60°C | Temporary sunshades, light cargo covers |

| Standard (0.45-0.55mm) | 500-650 | 2500-3000 | -20°C~70°C | Logistics tarps, outdoor tents |

| Heavy-Duty (0.6-0.8mm) | 700-900 | 3500-4000 | -30°C~80°C | Industrial dust covers, truck tarps |

| Extra-Heavy (0.9-1.1mm) | ≥1000 | ≥4500 | -40°C~100°C | Welding blankets, mine ventilation ducts |

Key Notes:

- Tear Resistance: Heavy-duty types (≥0.6mm) use 1000D×1000D polyester base fabric.

- Coating: Triple-layer PVC (UV-proof + waterproof + adhesive) for extended lifespan (4-10 years).

- Cold Resistance: DOS plasticizers maintain flexibility at -30°C (ideal for cold-chain logistics).

II. Thickness-Specific Applications

1. Ultra-Thin (0.2-0.3mm):

- Use Cases: Camping shades, market stall covers.

- Pros: Lightweight, portable, low cost.

- Cons: Weak wind resistance; avoid sharp objects.

2. Standard (0.45-0.55mm):

- Scenarios:

- Truck cargo protection (waterproof ≥2000mmH?O).

- Greenhouse curtains (UV-resistant additives).

- Features: Acrylic surface treatment for anti-slip performance.

3. Heavy-Duty (0.6-0.8mm):

- Industrial Uses:

- Welding blankets (flame-retardant additives).

- Port covers (titanate anti-corrosion coating).

- Safety: Heat-sealed edges + metal grommets.

4. Extra-Heavy (0.9-1.1mm):

- Extreme Environments:

- Mine ducts (abrasion/flammability resistance: Class B1).

- Oil rig covers (anti-static: surface resistivity ≤10?Ω).

- Reinforcement: Fiberglass base + PTFE coating (180°C short-term tolerance).

III. Selection Guidelines

1. Thickness ≠ Durability:

- Ultra-thin with 500D×500D base fabric may outperform low-density standard types.

- Prioritize "base fabric density + coating thickness" (e.g., 1000D base + 0.3mm coating > 500D base + 0.5mm coating).

2. Environmental Adaptation:

- High-temp sites (e.g., metallurgy) require heat-resistant series (120°C+).

- Coastal areas mandate ≥1.0% anti-mildew agents.

3. Cost Optimization:

- Non-long-term use (e.g., event tents): 0.45mm standard type (40% cheaper than extra-heavy).

- Bulk orders (≥5000m2): Heavy-duty (0.7mm) at reduced unit price (e.g., ¥5.64/m2).

> Golden Rule:

> - Portability: Ultra-thin (0.3mm) for temporary/home use.

> - Balance: Standard (0.55mm) for logistics/agriculture (best value).

> - Extreme Protection: Heavy-duty (≥0.8mm) for industrial/hazardous environments.

>

> Future Trend: "Smart thickness" thermo-responsive coatings (R&D phase) for dynamic adaptability.

All terms (e.g., phr = parts per hundred resin), units (N/5cm, GSM), and industry standards (RoHS, ISO) are preserved for technical accuracy.

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.