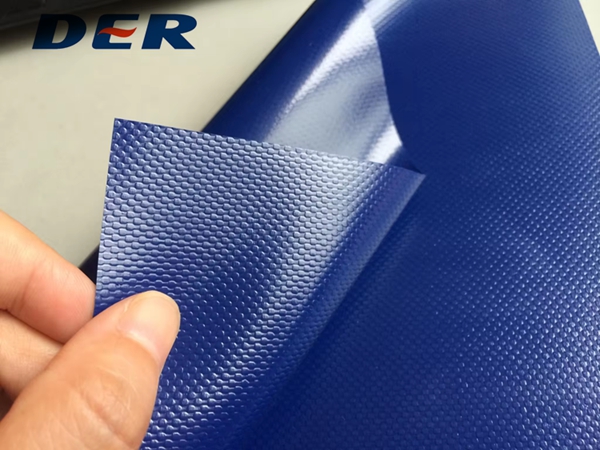

PVC TARPAULIN

- 2025-06-23

PVC Tarpaulin Anti-Mildew & Antibacterial Functions and Application Scenarios

I. Anti-Mildew and Antibacterial Technical Principles

1. Core Anti-Mildew Agent Types and Mechanisms

- Organic-Inorganic Composite Anti-Mildew Agents

- Organic Components (e.g., quaternary ammonium salts, phenolic derivatives): Rapid sterilization (effective within hours), immediate bacterial inhibition.

- Inorganic Components (e.g., nano-silver, zinc oxide carriers): Long-lasting mildew resistance (withstands >350°C), disrupt microbial cell structures via metal ions.

- Composite Advantage: Solves issues of fast dissolution and poor weather resistance in single-component agents; antibacterial rate >99%; mildew resistance grade 0-1 (highest standard).

- Low-Odor Eco-Friendly Formulation

- Tributyl citrate replaces traditional phthalate plasticizers, reducing VOC emissions.

- Hindered phenol antioxidants minimize processing odors.

2. Material Structure and Process Optimization

- Multilayer Design:

- Base Fabric Layer: High-strength polyester (warp strength ≥2100N/5cm).

- PVC Functional Layer: Anti-mildew agents (0.5-1.5 phr), halogen-free flame retardants (5-9 phr).

- Surface Treatment Layer: Secondary coating with anti-mildew agents (2.5-4 phr) for enhanced antibacterial properties.

- Key Processes:

- Staged Plasticization: PVC coating at 180-220°C; surface layer dried at 50-75°C to prevent agent decomposition.

- Curing: 5-7 days at room temperature to enhance cross-linking density.

II. Application Scenarios & Requirements

| Scenario | Core Needs | Anti-Mildew Solution | Additional Requirements |

| Medical Tents | High antibacterial, low odor | Dual-layer agents (4 phr total) | Fold resistance, ventilation compatibility |

| Logistics Tarps | Weather/mildew/rain proof | Composite agents (0.3%-0.5%) + anti-slip surface | Tear resistance (≥1600N/5cm) |

| Grain Storage Covers| Mildew inhibition, cold resistance | Cold-resistant plasticizers + 1.5 phr agents | UV resistance, -20°C tolerance |

| Welding Blankets | Flame retardant, anti-corrosion | Synergistic anti-mildew/flame retardant additives | Fire certification (≥1h resistance) |

| Outdoor Shelters | Long-term mildew resistance | Outdoor-specific agents (1.0%-1.5%) | Acid/alkali resistance, aging resistance |

III. Key Performance Metrics

1. Efficacy:

- Antibacterial rate >99% against E. coli and S. aureus.

- Mildew resistance grade 0 (no growth) against mixed molds (e.g., Aspergillus niger).

2. Environmental Adaptability:

- UV stability: 3-5 years outdoor service life.

- Temperature range: -20°C to 180°C (short-term).

3. Safety:

- Heavy-metal-free (RoHS compliant), non-carcinogenic (LD?? >5000mg/kg).

IV. Industry Trends

- Smart-Response Materials: Thermosensitive anti-mildew agents (e.g., low-temperature release).

- Renewable Additives: Epoxidized soybean oil replaces plasticizers.

- Digital Monitoring: Embedded sensors for real-time microbial status (R&D phase).

Summary: Prioritize ≥1.0% anti-mildew agents for humid environments. Medical use requires ISO 10993 biocompatibility tests. Standard logistics tarps suffice with 0.3% agents for cost efficiency.

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.