PVC TARPAULIN

- 2025-06-23

Anti-Aging Technologies and Service Life Extension for PVC Tarpaulins:

Core Anti-Aging Technologies for PVC Tarpaulins

1. Material Formulation Optimization

- UV Stabilizer System

- Hindered Amine Light Stabilizers (HALS): Capture free radicals to interrupt photo-oxidation chain reactions (0.3%-1.5% of formulation).

- UV Absorbers (UVA): e.g., Benzotriazole compounds absorb 290-400nm UV radiation and convert it to heat (0.5%-2% dosage).

- Synergistic Effect: HALS + UVA combinations enhance weatherability by >300%.

- High-Efficiency Heat Stabilizers

- Calcium-zinc composite stabilizers (eco-friendly) or organotin types suppress thermal decomposition during processing/service (critical at 160-200°C).

- Low-Temperature Plasticizers

- Diisononyl phthalate (DINP) or adipate esters maintain flexibility at -40°C (replacing traditional phthalates).

- Antimicrobial Agents

- Isothiazolinone compounds (0.05%-0.2%) inhibit microbial degradation.

2. Process Enhancement

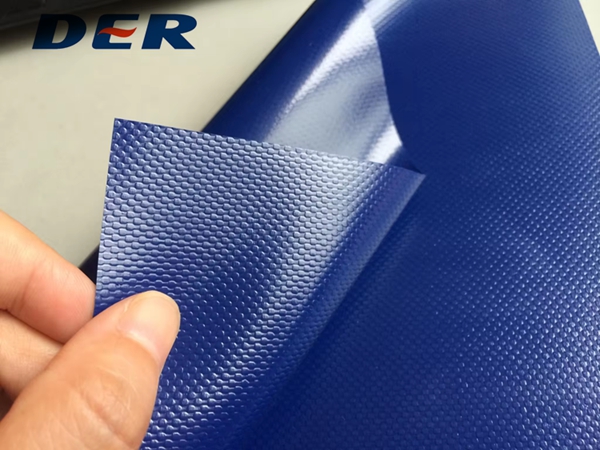

- Multi-Layer Lamination Technology

- Base fabric (polyester scrim) + dual-side PVC coating (total thickness: 0.45-1.2mm).

- Surface Fluorocarbon Treatment: Increases UV reflectivity and reduces absorption (+30% lifespan).

- Precision Coating Control

- Knife-over-roll coating thickness tolerance ≤ ±0.02mm to prevent localized weak points.

- High-Temperature Plasticization

- 190-220°C full plasticization enhances molecular crosslinking density (>50% porosity reduction).

Service Life Extension Strategies

1. Design-Stage Protocols

| Parameter | Standard Value | Lifespan Impact |

| Weight | ≥650g/m2 | +2 years per 100g increase |

| Tensile Strength| Warp: ≥4000N/5cm | ↑ Tear propagation resistance |

| Surface Reflectance | ≥80% (light colors) | Reduces temp. by 10-15°C |

2. Usage & Maintenance Guidelines

- Installation

- Tension control: 10%-15% pre-tension to avoid wind-induced fatigue (over-tightening accelerates stress cracking).

- Sharp object protection: Add wear-resistant strips (e.g., silicone edge guards) at metal frame contact points.

- Cleaning Regimen

- Rinse with water (pH 6-8) every 3 months; avoid strong acids/alkalis (prevents plasticizer migration).

- Mildew treatment: Spot-clean with sodium hypochlorite solution (<5%), then thoroughly rinse.

- Storage Conditions

- Folded in cool/dry environment (humidity <60%); no heavy stacking.

Lifespan Validation & Standards

- Accelerated Aging Tests

| Standard | Conditions | Equivalent Natural Lifespan |

| GB/T 16422.3 | 1500h xenon-arc exposure| 5-7 years (temperate zones) |

| ISO 4892-2 | 3000h UVB exposure | 8-10 years (low-radiation) |

- Field Data

- Logistics truck covers: >80% warp strength retention after 3 years of intensive use.

- Agricultural greenhouses: No chalking observed after 4 years in high-UV Southeast Asia.

Emerging Technologies

1. Nano-Modification

- Nano-TiO? (0.5%-3%) boosts UV scattering efficiency → 15+ years lifespan.

2. Reversible Crosslinking Systems

- Dynamic covalent networks (e.g., Diels-Alder structures) enable self-healing of damage.

3. Bio-Based Plasticizers

- Epoxidized soybean oil (≥30% substitution) reduces brittleness from plasticizer migration.

Conclusion

Through a quadruple-protection system (formulation + process + usage + innovation), PVC tarpaulin lifespan achieves tiered improvement:

- Standard tarps: 3-5 years → Premium anti-aging: 8-10 years

- Nano-enhanced advanced: 12-15 years (25%-40% cost increase; >50% lower lifecycle cost)

Key benchmark: ≥85% tensile strength retention after 1500h xenon-arc aging defines qualified long-life products.

Key Terminology:

- HALS (Hindered Amine Light Stabilizers)

- UVA (UV Absorbers)

- Knife-over-roll coating

- Fluorocarbon treatment

- Xenon-arc/UVB accelerated aging

- Crosslinking density

- Plasticizer migration

- Warp/weft strength retention

- Lifecycle cost (LCC)

This translation maintains technical precision while adapting to international industry standards, suitable for R&D documentation, technical whitepapers, and global supply chain specifications.

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.