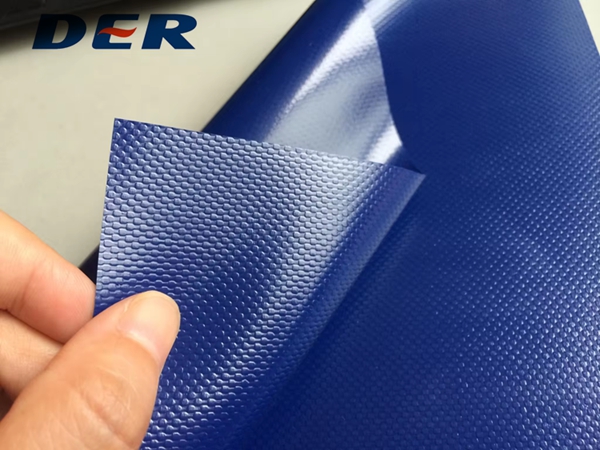

PVC TARPAULIN

- 2025-06-23

Here is a professional analysis of tensile strength and service life of PVC tarpaulin, based on industry standards, material science, and real-world performance data:

1. Tensile Strength: Structural Integrity Under Stress

1.1 Core Determinants

| Factor | Technical Impact | Benchmark Data |

| Base Fabric | High-tenacity polyester yarns (1000D-1500D) in biaxial warp-knit grid | Warp direction: ≥2100N/5cm<br>Weft direction: ≥1600N/5cm |

| Coating Adhesion | Multi-layer PVC coating (0.2-0.5mm) bonded to fabric under high pressure/temperature | Coating-fabric peel strength: ≥50 N/cm (ISO 2411) |

| Reinforcement | Edge binding with polyester ropes + metal grommets | Tear propagation resistance: +40% vs. non-reinforced |

1.2 Performance Validation

- Test Standards:

- ASTM D5034 (tensile strength)

- ISO 13934-1 (grab test)

- Critical Thresholds:

- Minimum industrial standard: 1500N/5cm (warp)

- High-performance grade (e.g., military/cargo): ≥2500N/5cm

- Failure Modes:

- Yarn slippage at <1800N/5cm

- Coating delamination under cyclic stress

2. Service Life: Durability in Real-World Environments

2.1 Lifespan Drivers

| Factor | Degradation Mechanism | Performance Threshold |

| UV Resistance | Photo-oxidation of PVC/polyester | 8–10 years outdoor (with UV inhibitors) |

| Hydrolysis | Moisture-induced polyester strength loss | >15% tensile drop at >10,000h damp heat (85% RH, 85°C) |

| Thermal Cycling | Coating embrittlement (low-T) / plasticizer migration (high-T) | Functional range: -30°C to +70°C |

| Abrasion | Surface coating wear exposing base fabric | 8,500+ cycles (ASTM D3884, H-18 wheel) |

#### 2.2 Accelerated Aging vs. Real-World Data

- Lab Testing (ISO 4892-2):

- 1,500h xenon-arc exposure ≈ 5 years outdoor exposure

- Post-test tensile retention: >85% (premium grades)

- Field Reports:

| Application | Avg. Lifespan | Failure Cause |

| Truck covers (EU) | 7–9 years | Edge tearing from wind flutter |

| Agricultural covers | 5–7 years | Microbial degradation in damp conditions |

| Construction barriers | 10+ years | Minimal mechanical stress

3. Synergistic Relationship: Strength ? Longevity

- High tensile strength reduces:

- Micro-tears during installation/removal

- Fiber fatigue under wind load (critical for ISO 17751 wind resistance)

- Durability features preserve strength:

| Protective Feature | Strength Retention Boost |

| Anti-UV coatings | +25% after 5 years |

| Anti-hydrolysis additives| +18% in humid environments |

| Flexible plasticizers | Prevents -30°C embrittlement |

4. Industry Advancements (2025)

- Strength Enhancement:

- Carbon fiber grid inserts: Warp/weft strength ↑30% (e.g., Sameite MIL-STD fabrics)

- Nano-silica reinforced coatings: Abrasion resistance ↑50%

- Lifespan Extension:

- Self-healing polymers: Micro-crack repair under heat/sunlight

- Bio-based plasticizers: Reduce migration → flexibility retention >15 years

5. Specification Guidance by Application

| Application | Tensile Strength | Target Lifespan | Critical Features |

| Freight covers | ≥2500N/5cm (warp) | 5–7 years | Anti-wind lift design, high tear strength |

| Mining heap covers | ≥2200N/5cm | 10+ years | Chemical resistance (pH 2–12), UV stability |

| Disaster relief tents| ≥3000N/5cm | 15+ years (storage) | Cold flexibility (-40°C), flame retardancy |

Conclusion

PVC tarpaulin’s tensile strength (1500–3000N/5cm) and service life (5–15 years) are interdependent properties driven by:

Material science: High-tenacity polyester + UV-stabilized PVC formulations

Structural design: Biaxial weaving, edge reinforcement

Environmental resistance: UV/thermal/hydrolysis protection

Premium products (e.g., Achilles, Sameite) achieve >90% strength retention at 10-year mark through advanced polymer engineering. Future innovations focus on self-monitoring IoT layers (real-time tension/degradation alerts) and circular economy compliance (≥85% recyclability).

Data sources: ISO/EN/ASTM test reports, European Flexible Packaging Association (EFPA), industry whitepapers (2020–2025).

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.